.png)

How Permian operators can diagnose & mitigate unlit flares.

In a new report by Validere and East Daley Analytics, analysis shows gas bottlenecks in the coming years that mean increased risks of Permian flaring and methane emissions. While there are many factors at play, one area where operators can make an impact is addressing unlit flares.

As the report notes, most emissions estimating methods include the assumption that 98% of the gas sent to flare is combusted (this includes the U.S. Greenhouse Gas Reporting Program). In other words, regulatory reporting tends to assume that 98% of flare gas is burned (converting the hydrocarbons to CO2), with just 2% emitted directly to the atmosphere. But since flaring is dynamic, there are several scenarios that can result in departures from 98% combustion.

One of those scenarios is when flares are completely unlit, operating as a cold vent and emitting 100% of the flare gas directly to the atmosphere. While most flares operate normally and burn almost all of the flare gas, the potency of methane as a greenhouse gas means that the implications for greenhouse gas emissions are profoundly different depending on whether the number flares that are unlit or improperly combusting is 2% or 10%. In a late 2022 study, a team of University of Michigan and Stanford researchers estimated 91% flaring efficiency due to a combination of unlit flares and degraded combustion efficiency at operational flares.

Because of some nuances around the difference between the number of flares versus flare volume, in Validere’s view, aggregate combustion efficiency across the Permian Basin is likely better than the 91% estimate. But regardless of true combustion efficiency, rising flaring rates are likely to bring increased scrutiny on Permian methane emissions, meaning heightened need for operators to ensure flares are operating properly.

Using operational data to identify unlit flares.

In recent years, operators have significantly increased spending on environmental monitoring, deploying a wide range of new measurement technology, including aerial surveys and fixed monitors. Typically mounted around the perimeter of a site, fixed monitors measure methane concentrations continuously and report these figures to operators. Relative to all other measurement options, they have the distinct advantage of taking continuous measurements.

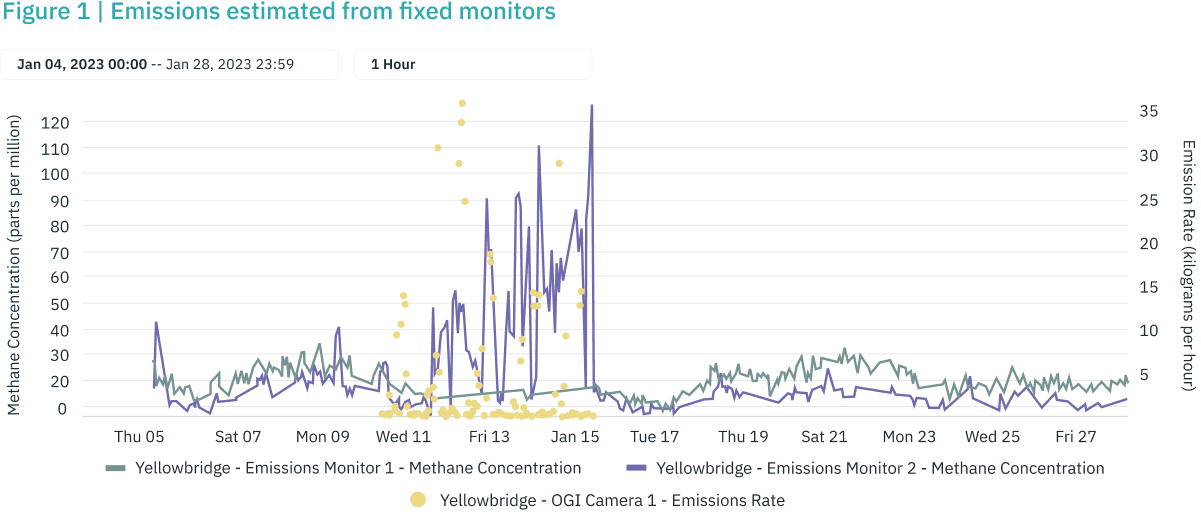

An example of continuous monitoring data is shown in Figure 1, including methane emissions concentration data (purple and teal) from two fixed point source monitors and emission rate estimates derived from a stationary quantification optical gas imaging (OGI) camera (yellow). Emissions monitor 2 (purple) and the OGI camera both reveal an emissions event, where the point source monitor is located downwind of the flare and the OGI camera is positioned to enable flare observation. Neither monitoring source provides a reliable quantification of the emissions event relative to the flow meter totalizing the flare gas flow, but both promptly identify the emissions event.

Source: Validere Carbon Hub

The more important good news for operators, however, is that this event was also observable by monitoring operational data, even absent independent methane continuous monitoring data. Thus, operators do not necessarily need to invest in fixed monitors to effectively reduce an important source of flare gas methane emissions — those from unlit flares.

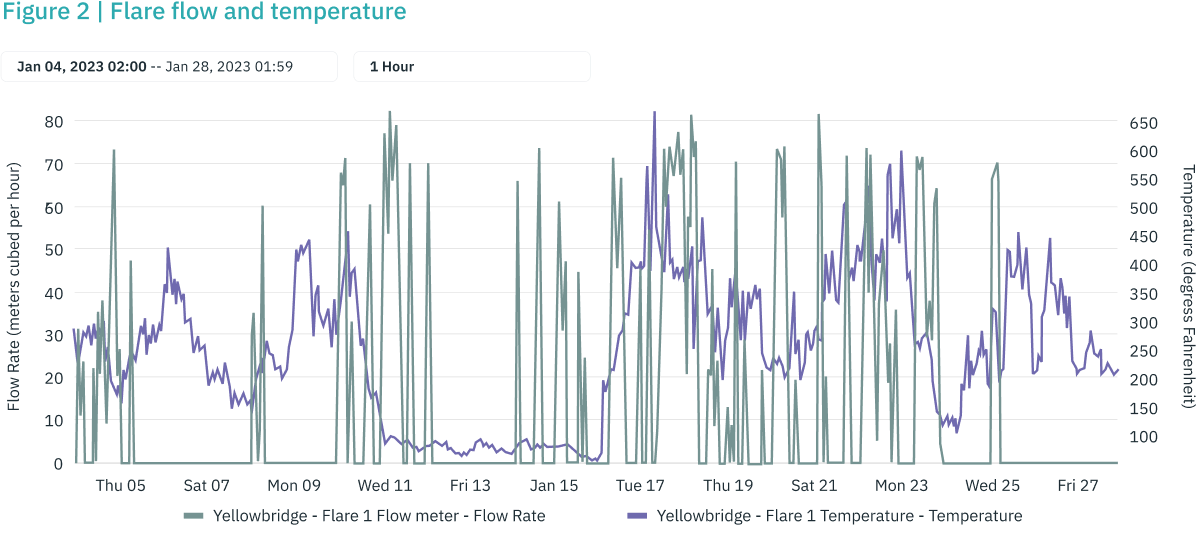

Regulations, such as the general provisions for the U.S. New Source Performance Standards (40 CFR 60 subpart A), require flares to be operated with a flame present at all times, and assure the presence of a flare pilot flame via monitoring using a thermocouple or an equivalent device to detect the presence of a flame. From operational data (Figure 2) for the same site and time period, an operator can see whether gas is flowing into the flare (green line), along with the temperature reading from the thermocouple (purple line). By effectively ingesting, monitoring, and alerting readings from existing thermocouples — such as with Validere’s Carbon Hub — operators can quickly diagnose and mitigate unlit flares.

Source: Validere Carbon Hub

Download the full report to learn more about flaring, methane, and the cost of looming Permian gas takeaway constraints.

Validere

Validere provides a powerful platform designed to streamline operations and enhance decision-making in energy organizations. Our integrated solutions leverage data, automation, and predictive analytics to improve operational efficiency while addressing critical challenges in emissions management, environmental health and safety (EH&S), and measurement.